One of our biggest involvement is the maritime market. In multiple ways, ships are responsible for environmental pollution. However current trends of the market are limiting environmental impact like Exhaust Gas treatment system. We are happy to present one of the ways, which reduces the amount of emissions and makes our world a better place.

WWT involvement in the Exhaust Gas Treatment market

In WWTechnic we focus on expertise in the commissioning and successful delivery of different engineering projects. It is important to serve our clients in a professional way. Therefore we are proud to build a team of professionals in the scrubber domain. Our scrubber team contains 5 experts: Zbigniew Mikulski, Antoni Jarmolski, Piotr Drozd, Radosław Wróblewski, Michal Surmacz and Przemysław Kwiecień.

Our team

This is our strong team with over a decade of experience in automation field in various industry sectors. Zbigniew and Antoni have the longest experience on-site and within scrubbers. Piotr a ‘scrubber doctor’. He solves even the most complex issues. Michal is a strong support in the commissioning phases and feels the best in this field. Przemek supports all and is usually involved in service works. We knew each other very well, worked together many times, and may count on each other. Proper experience, good atmosphere and trust are the basis.

Picture by Michał Surmacz

Over the last 2 years, this team has been involved in the successful realization of multiple projects. We realize both retrofit and new build installations for our clients. This includes newbuild units like Wonder of the Seas – up to now the biggest cruise ship in the world,

Picture by Michał Surmacz

but also retrofit projects on Oasis, Mariner, Allure, and Navigator of the Seas. We have not been limited to Royal Caribbean ships, we also realized Celebrity Reflection and Celebrity Equinox. Our Team has realized all these projects in a full scope. This includes supervision of installation, pre-commissioning activities, commissioning, sea trials, fine-tuning, and training of a crew.

WWTechnic teamwork as a key to execution

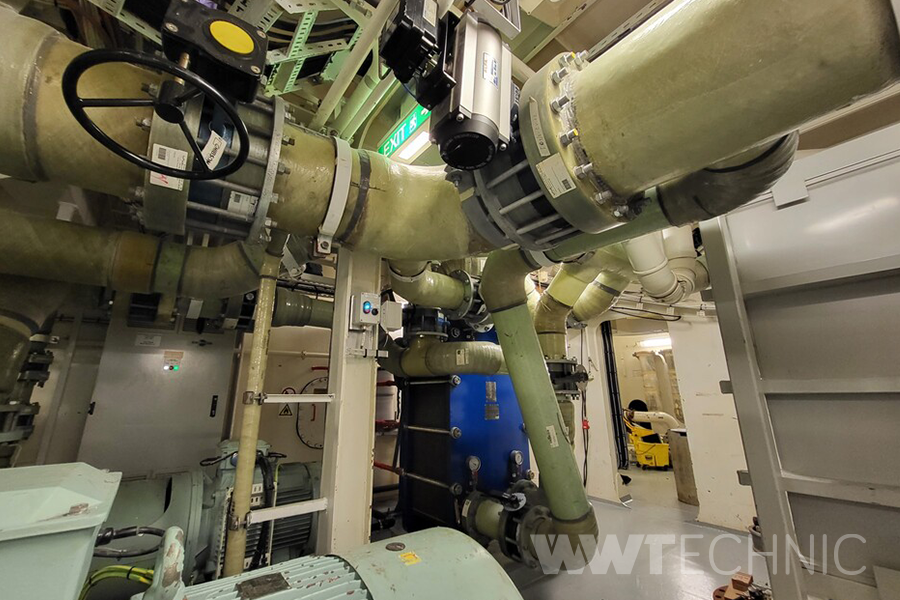

Each realization has a dedicated team, which works together on the project. It’s always a challenge to realize such complex projects in a limited time frame. Each project starts with setting up a work procedure. We need to check if all components are installed properly, and if each component is ready to perform as part of a bigger system. We supervise the installation of the last components, with the perspective of orchestration of the complete system. Orchestration includes mechanical components, electrical and automation systems. So the scope of the components and processes is quite complex.

Project steps

As a next step, we do the commissioning of the system. This very often includes Harbour Acceptance Test (HAT), which needs to be class-approved. During this phase, we present the overall operation of the system. This stage is something like an idle run of the engine. Our next goal is to present a successfully operating system during the sea trials. During the sea trials, we are busy with tuning of the system. Each engine is a bit different, therefore we must do the final adjustment of every system separately.

One of the most important parts, mainly to the ship owner is Marpol test. This is to present class representatives proper functionality of the system, to prove that exhaust gases and water quality are within the limits and the safety part of the system. Once Marpol is approved ship is certified to use the scrubber.

The last stage of our involvement is the training of the crew. We need to hand over fully operating system and explain to the ship crew how to use the system. After this stage, we end the project. The whole sequence is usually realized by a team consisting of 2 engineers.

Picture by Michał Surmacz

Cruise ship industry – Reduce environmental impact

Over the last 3 years, we realized multiple projects, which are important for the sustainability of our planet. At WWTechnic we are happy to realize environmentally important projects. We already presented You Waste to Energy and LNG hybrid power generation. We love to be involved in a green future. Exhaust gas treatment technology has a serious impact on the environment by reducing NOx and SOx emissions into the atmosphere. How does this technology impact the environment?

The technology behind Exhaust Gas Treatment Systems

Most of the ships today operate on Fuel Oil. Globally, we are working on the reduction of the emissions. Ships fuel consumption is calculated in tons per hour. Each ton of marine fuel contains up to 3,5 % of sulfur. Sulfur combines with oxygen and forms sulfur oxides, so-called SOx – SO2, and a small amount of SO3 in the exhaust. The release of the SOx into atmosphere combined with water creates acid rain.

Picture by Michał Surmacz

The average marine diesel engine produces a lot of particulates. Therefore limitation of exhaust pollution has a great impact on the environment. But how to achieve it?

Scrubber – Key word in Exhaust Gas Treatment

A scrubber is a pollution control device. They are used to reduce sulfur oxides from ship engines’ exhaust gases. We have 3 types of scrubbers on the market:

Open loop type Exhaust Gas treatment system

Open loop scrubber – These scrubbers operate by using seawater as the absorbent. In the open loop system, seawater is sprayed directly into the exhaust gas stream, reacting with the sulfur oxides to form sulfate compounds. The resulting washwater, containing the dissolved pollutants, is then discharged back into the sea. While open loop scrubbers are cost-effective, concerns have been raised about the environmental impact of discharging treated washwater into marine ecosystems.

Picture by Przemysław Kwiecień

Closed loop type Exhaust Gas treatment system

Closed loop scrubber – In a closed loop exhaust gas cleaning system, a circulating fluid, usually sea water or its combination with fresh water, with added alkaline chemicals (i.e. NaOH or MGO) is used to absorb sulfur oxides from the exhaust gas. The mixture is then circulated and sprayed back into the system. This closed system prevents the direct discharge of the washwater into the sea, addressing environmental concerns associated with open loop scrubbers. The absorbed pollutants react with the alkaline solution, forming solid by-products that are collected and disposed of properly. Closed loop scrubbers are suitable for areas where strict regulations govern the discharge of pollutants into the environment.

Hybrid type Exhaust Gas treatment system

Hybrid scrubber – Hybrid scrubbers combine features of both open loop and closed loop systems, offering flexibility to ship operators. In hybrid mode, the scrubber can operate either as an open loop or closed loop system, allowing ships to adapt to varying environmental regulations and conditions. This versatility is particularly valuable when vessels transition between areas with different discharge regulations. Hybrid scrubbers typically include a bypass option, enabling the ship’s crew to choose the most suitable mode based on factors such as sea conditions, proximity to coastal areas, and compliance with regional environmental standards. This adaptability makes hybrid scrubbers a popular choice for shipowners seeking a balanced and compliant solution.

Scrubber realizations

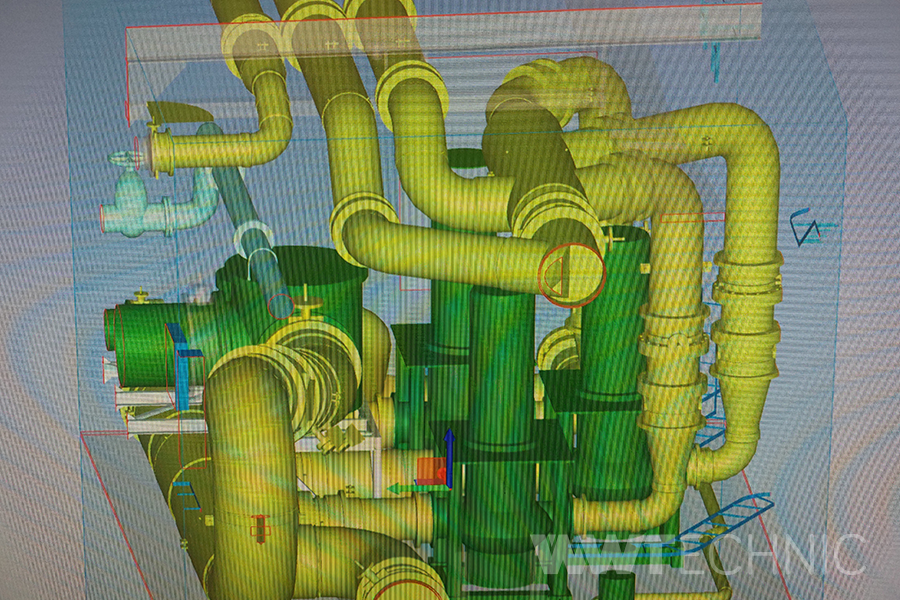

At the moment we mostly realize the hybrid systems, I-Sox – Inline scrubber and V-Sox Venturi Type, produced by Wartsila.

Venturi Scrubber – This is an integrated system, designed to clean exhaust gases from several auxiliary engines. This means that 1 scrubber is responsible for cleaning the exhaust of multiple engines. Such a system is perfect for newly built ships, which operate with many auxiliary engines.

I-Sox scrubber is a reduced-size system. It’s used especially for retrofit projects

Picture by Michał Surmacz

Scrubber – Real emissions impact

While scrubbers contribute to cleaner air by reducing sulfur emissions from ships, there are ongoing discussions and regulatory developments concerning the environmental impact of scrubber discharges, especially in open loop systems. Striking a balance between achieving air quality benefits and addressing potential water quality concerns remains a key consideration in the use of scrubbers.

Environmental impact as our goal

In WWTechnic we tight mainly to environmental projects. We love sustainable projects. As the marine industry is responsible for producing a lot of pollution, we are happy to be involved in PMSG and scrubber projects to limit this impact. We are proud to work with customers who share the same goals as we are. If You are looking for a business partner or an environmentally important position. In short, feel free to reach out to us!

And the most important, We are actively recruiting! Therefore apply here!